Automotive Heating Systems for the Automotive Sector

Applications and Products

We collaborate with you to develop solutions for the heating requirements of the automotive industry. Whether air, water, diesel or AdBlue – you can tap into our decades of experience in the field of electrical heating systems.

As one of the market leaders in the area of heated SCR systems, we recognize the importance of more rigorous environmental requirements (Euro 6 standard), the growing demand for comfort and safety and the need for optimized consumption, and we join forces with you to develop your specific solution, whether in the passenger car or commercial vehicle field.

Overview Application Fields

Exhaust Gas Treatment

Fuel Pre-Heating

Intake Air Duct

Cooling Circuit Control/Wire Heating Elements

Fluid-Conveying Pipes

Electric Mobility / Alternative Drive Forms

Application Fields and Products

Without exhaust gas treatment, it would not be possible to adhere to the more rigorous worldwide environmental and exhaust emissions standards (including Euro 6). Here you will find some of our answers to these technological challenges.

SCR - selective catalytic reduction

In modern diesel engines, subsequent treatment of the exhaust gases produced as a result of combustion is required to meet the demands of the Euro 6 standard. Here, an aqueous urea solution (Adblue/DEF) is dosed into the exhaust gas system that reduces nitrogen oxides in the catalytic converter. Since the additive freezes at low temperatures (from -11°C/52F), all components carrying Adblue must be heated.

In this segment we offer solutions for heating systems positioned at specific points or over a surface based on PTC or regulated fixed resistor technology.

In the case of PTC Technology, we generally use our patented manufacturing method, which guarantees a highly-efficient transfer of energy to the medium to be heated.

For applications on a surface structure, we draw on our years of experience in the field of plastic coated (fixed resistor) lead frames. In combination with our patented control system for lead frames, we can provide you with a low-cost solution for surface applications.

The high degree of freedom in terms of shape design allows considerable flexibility when integrating the heating system in the customer’s SCR module.

In addition to complying with statutory requirements in terms of required thaw quantities/times, our heating systems also meet increasing demands for sealing tightness and service life in direct contact with Adblue/DEF due to efficient application of the heat output. Various output categories are available to choose from.

In everyday life, we have become accustomed to the high efficiency and broad range of uses offered by diesel engines, even under demanding operating conditions. Electrical heating systems are among the features that ensure reliable operation, even at low ambient temperatures.

Since Diesel fuel is subject to wax precipitation: this results in high viscosity, making it more difficult to start and run the engine. Diesel-carrying components such as the filter are heated with an electric element to ensure sufficient flow of the diesel fuel and maintain the capacity of the engine to start and run

Diesel Filter Heater

Eichenauer's diesel heaters can work on a through-flow or surround-flow basis for operation directly in the oil sump of the filter or near the water separator if necessary.

The heaters can be operated in the range of 12 – 48 volts and fitted with or without an electronic unit (intelligence, control etc.), according to customer preference.

The latest generation of our diesel heaters features our patented heater package structure. This allows us to achieve the highest level of output in the smallest installation space available on the market, keeping on-board power system load as low as possible to the benefit of our customers.

We will be glad to integrate fuel pre-heating directly in your components such as filter housings, filter caps and fluid ducts, or supply them pre-installed.

Tried and tested in millions of products – get in touch with us.

We offer you a wide range of OBD-capable air ducts and blow-by lines (for your crankcase ventilation) – including plastic corrugated tubing, hose piping in rubber and combinations of plastic and metal pipes.

Some of our products are designed for long-term durability when used at temperatures of up to 200°C/392°F.

In addition to the OBD diagnosis, we will be pleased to integrate functions for pressure and through-flow measurement, as well.

If the feed point requires heating, we will engineer a heating element solution specific to your application.

Blow-by

Due to its compact design, the Eichenauer blow-by heater fits in the most restricted installation space.

Power consumption is always of paramount concern; Eichenauer's patented solution – found in many customer applications – guarantees extremely fast thawing times and the lowest power requirements.

Our modular integration allows us to create prototypes and scale to volume-production applications very quickly.

Crankcase Ventilation

Blow-by gases always occur in the crankcase of combustion engines. Since the crankcase forms a closed space together with its attachment parts (cylinder head, oil sump etc.), there would be a constant increase in pressure if there were no ventilation. To avoid this, blow-by gases containing combustion products and unburned hydrocarbons are discharged from the crankcase. The ideal crank chamber pressure is in the negative range around −2 mbar, since the engine does not tend to bleed oil under these conditions. If the negative pressure is significantly greater (the level depends on the engine and the design of the sealing joints), there is a risk of the air being drawn in with dirt particles via the shaft sealing rings and crankcase seals. This would result in increased wear and tear of the inner components. During ventilation, droplets of oil from rotating components are inevitably forced out of the crankcase, too.

The oil content in blow-by systems depends heavily on the medium pressure, the pairing of the cylinder piston ring and liner and the extraction point (position and cross-section) on the engine.

Nowadays, new technologies help improve the efficiency and combustion quality of engines to approach optimum level.

One key aspect here is regulating the operating temperature of the engine by means of a controlled cooling circuit to a constant optimum temperature of 110°C/230°F in all the various driving situations and engine operating states that typically occur on a day-to-day basis. Thermostats are deployed in the cooling circuit for this purpose, with significant benefits in terms of fuel consumption, exhaust emissions and engine service life.

Map-Controlled Thermostat

Electronic map-controlled thermostats are the latest generation of thermostats, following on from conventional thermostats.

These units feature an electrically controlled heating element integrated in wax as an expansion material. The heating element is controlled based on a MAP sensor in the engine control unit and heats the expansion material, thereby causing the cooling circuit to open via the thermostat valve.

This allows the thermostat to impact on engine temperature much more quickly, ensuring the optimum range is maintained in the various load and operating states.

Our wire heating element is the centerpiece of the latest generation of thermostat supplied to our customers: it features very short reaction times and fast response to the heating of the expansion material.

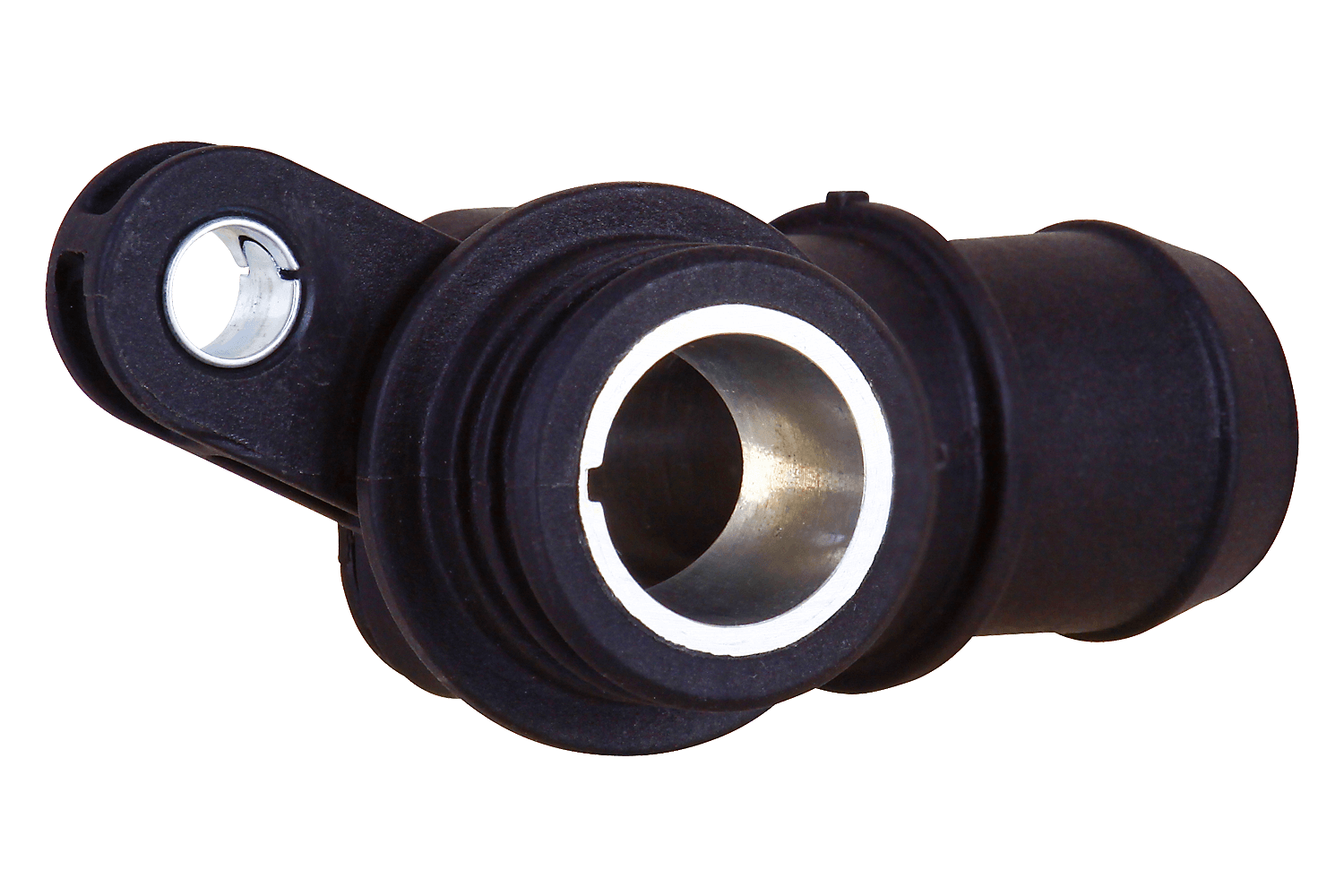

Fluid-Conveying Pipes

Fluid-conveying pipes are to be found in a wide variety of systems in the automobile, including SCR, fuel, coolant and brake systems, each performing a different function.

Eichenauer manufactures fluid-conveying pipes in both heated and non-heated form.

Here we draw on our longstanding experience of pipe production for diameters from 4 to 30 mm using all common materials – from aluminum, steel, stainless steel and copper through to wrought nickel alloys.

Our standard processes include cutting to length, washing, reshaping (e.g. widening, contraction, flanging) and bending.

We will be pleased to produce your shaped pipe with soldered, welded or molded holders, seals or hydraulic connectors.

Various facilities and devices are available for soldering and welding (MIG, laser) of modules as well as for the injection-molding and assembly of thermoplastic or elastomer components. Years of experience of using testing technology for large-scale series ensures the very highest quality as well as guaranteeing adherence to customer specifications.

We supply everything from the simple, fluid-conveying pipe through to fully assembled modules of varying complexity.

The shift from conventional drive technology in motor vehicles towards alternative forms of propulsion such as electric motors and fuel cell applications has gained in momentum in recent years and will have a major impact on the automobile of the future.

This has led to new challenges in terms of thermal management in cars.

Efficient heating of the interior, temperature control of additives and maintaining technical functions such as eliminating ice and condensation are just some of the key functions.

The use of electrical heating systems can contribute to the development of solutions in this field.

Electric Mobility

Electrically powered vehicles with and without range extender and plug-in hybrids do not generate enough additional heat to warm up the interior of the vehicle when travelling in electric mode. One remedy here is to install electric auxiliary heaters in the coolant water circuit or the air duct of the HVAC module.

For this purpose, Eichenauer offers heating systems based on tubular heating element technology. These can be used to cover a broad operating voltage range, with a heating capacity of up to 8KW. Very low start-up currents are possible here – in contrast to PTC technology. The regulation and protection of the heating system is taken care of by an intelligent electronic system.

Compact auxiliary PTC heaters can be integrated in the outlets of the various air intake ducts for decentralized auxiliary heating at the rear of the passenger cell. These ensure specifically targeted heating and are self-regulating, covering an output range of 80 to 300W.

In addition to the extra comfort provided by an electric auxiliary heater, technical functions such as battery temperature control and quick defrosting of the windscreen are also an issue.

We will be glad to collaborate with you and contribute our broad experience in these areas to develop your customer-specific solution.

Fuel Cell

Operation of a fuel cell results in the discharge of deionized water. At low temperatures, Eichenauer valve seat heaters ensure reliable operation as well as short response and thawing times.

We regularly generally provide a solution to customer-specific heating requirements by adapting one off our standard products.